1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

125

126

127

128

129

130

131

132

133

134

135

136

137

138

139

140

141

142

143

144

145

146

147

148

149

150

151

152

153

154

155

156

157

158

159

160

161

162

163

164

165

166

167

168

169

170

171

172

173

174

175

176

177

178

179

180

181

182

183

184

185

186

187

188

189

190

191

192

193

194

195

196

197

198

199

200

201

202

203

204

205

206

207

208

209

210

211

212

213

214

215

216

217

218

219

220

221

222

223

224

225

226

227

228

229

230

231

232

|

[[!toc levels=2]]

#Introduction

The goal is to make a small laser CNC machine that has a cutting spot of <10 microns.

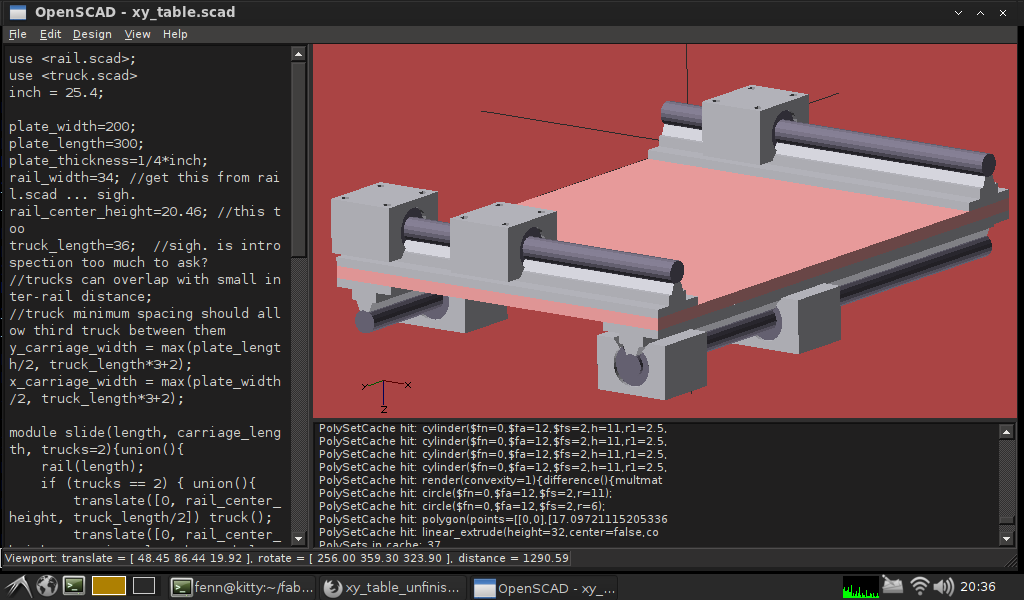

# rendering

## unfinished CAD items

* it's missing the top and bottom plates, the bolt hole locations, the leadscrews and leadnuts and bearing mounts and stepper motor mounts, and it needs some kind of right angle bracket to hold the laser optics (i was thinking some kind of optical breadboard at 90 degrees to the motion stage... )

## assembly notes

fenn: I'm not sure the dimensions work the way i had imagined, but it should be close enough to take out any vertical slop with shims

# items with source needed

* This is to prevent an eccentric leadscrew from causing uneven friction with the nut, and to prevent side loading of the axis

* [http://www.thingiverse.com/image:11683]

# parts procurement

Spreadsheet here: [https://docs.google.com/spreadsheet/ccc?key=0AkTsdtdxo56DdFVYWkd4YjhKVmdfSk1WV1ZpZ2F5enc](https://docs.google.com/spreadsheet/ccc?key=0AkTsdtdxo56DdFVYWkd4YjhKVmdfSk1WV1ZpZ2F5enc)

<iframe width='100%' height='300' frameborder='0' src='https://docs.google.com/spreadsheet/pub?key=0AkTsdtdxo56DdFVYWkd4YjhKVmdfSk1WV1ZpZ2F5enc&output=html&widget=true'></iframe>

gantry:

[[!table data="""

item, quatity, price, link

rail, 1, $99.00, [http://www.vxb.com/Merchant2/merchant.mvc?Screen=PROD&Store\_Code=bearings&Product\_Code=Kit8279&Category\_Code=12mmLinearMotionSystems](http://www.vxb.com/Merchant2/merchant.mvc?Screen=PROD&Store_Code=bearings&Product_Code=Kit8279&Category_Code=12mmLinearMotionSystems)

trucks, 6, $9.95, [http://www.vxb.com/Merchant2/merchant.mvc?Screen=PROD&Store\_Code=bearings&Product\_Code=Kit8512&Category\_Code=12mmLinearMotionSystems](http://www.vxb.com/Merchant2/merchant.mvc?Screen=PROD&Store_Code=bearings&Product_Code=Kit8512&Category_Code=12mmLinearMotionSystems)

thrust bearing 8mm ID x2, 2, $14, [http://www.vxb.com/page/bearings/PROD/Thrust/Kit7153](http://www.vxb.com/page/bearings/PROD/Thrust/Kit7153)

ball bearing 8mm ID 16mm OD, 2, $1, [http://www.vxb.com/page/bearings/PROD/8mm/688ZZ-1](http://www.vxb.com/page/bearings/PROD/8mm/688ZZ-1)

bearing block, 2, $10, [http://www.vxb.com/page/bearings/PROD/kit7136](http://www.vxb.com/page/bearings/PROD/kit7136)

3/8-40 acme wear-compensating nut, 2, $35.03, mcmaster 6350K213

3/8-40 acme threaded rod, 1, $157.36, mcmaster 6350K137

spring washer (wave washer for thrust bearing preload), 2,

helical coupler, 2,

stepper, 2,

"""]]

laser:

test Blu-Ray 12X BD-R drive, contains at least 700mW 405nm laser $100 newegg

if that works, try replacing the diode with 1W version from ebay (or 2W 445nm laser), custom beam expander and may be required but should be pretty cheap and easy

# design

bearings are needed to prevent the screw from whipping around, as it will be rotating at about 1000rpm. instead of

making bearing blocks we can(?) buy shaft holders from vxb, sized to fit the OD of the bearing. then, two thrust

bearings go on either side of the shaft block, constraining the leadscrew in the axial direction. the leadscrew ends

are machined to have a shoulder and a capture nut. the stepper motor drives the other end of the screw with a helical

coupler or diaphragm joint and prevents it from whipping around. (?)

kinematic design to prevent binding and flexing. each axis has 3 trucks, 2 on one rail, 1 on the other rail.

grouted construction (moglice epoxy to bed components)

shims to align components vertically

granite or mic-6 plate, as most convenient

# optics calculations

referencing the paper "Characterization of Program Controlled CO2 Laser-Cut PDMS

Channels for Lab-on-a-chip Applications", available from the publisher and at

[http://fennetic.net/irc/laser\_ablation\_profile\_power.pdf](http://fennetic.net/irc/laser_ablation_profile_power.pdf)

fig.7 in the paper shows a full-depth (trapezoidal) channel, cut at "25% speed"

after searching through the paper for values because of the obnoxious lack of units in their graphs, we find the

parameters used to be:

channel width: 700um

film thickness: 381um

laser wavelength: 10600nm

cutting speed: 254cm/s (wow!)

cutting power: 60W

this works out to give a power density of 60W/(700micron*0.25*254cm/s)

= 13.5 J/cm^2

and assuming a full-depth cut, 60W/(381micron*700micron*0.25*254cm/s)

= 354 J/cm^3

# cut speed calculations

We'd like machining time for large single-layer designs to take 15 minutes to fully finish, to allow for rapid revision of digital to physical design. That math is:

1,000,000 droplets 25 microns in diameter next to each other single-file * 1.25 for overheard and reaction centers that use the droplets. That's 31,250,000 microns for a single layer (the other layer or two would be much much less).

31,250,000 microns == 31,250 mm

31250 mm / 15 minutes = 2083mm/min

2083 mm/min == 33966.66 microns/second

with a 40 tpi screw and 400 step/revolution stepper motor:

25400 microns (1 inch) / 40 / 400 steps = 1.5875 microns per step

1.5875 microns/pulse -- full-step that speed requires 21396.32 hz pulses

0.1984375 microns/pulse -- 1/8th microstepping requires 171khz

0.09921875 microns/pulse -- 1/16th microstepping requires 342khz

# optics equations/calculators/software

[http://buildlog.net/cnc\_laser/laser\_calcs.htm](http://buildlog.net/cnc_laser/laser_calcs.htm)

[http://www.newport.com/Laser-Damage-Threshold/144932/1033/content.aspx](http://www.newport.com/Laser-Damage-Threshold/144932/1033/content.aspx)

Laser Parameter Calculator

[http://laserpointerforums.com/f51/lpc-laser-parameter-calculator-check-out-your-mrad-56454.html#post797367]

DrGeoffA @LensDesignApps News on lens design apps - optical design software - PreDesigner, WinLens3D & MachVis

[http://twitter.com/lensdesignapps]

* gOptical - class for aspheric (curved polynomial) lenses; gOptical tutorial

* [http://www.gnu.org/software/goptical/manual/Curve_Polynomial_class_reference.html]

* [http://www.gnu.org/software/goptical/manual/Tutorial.html]

# optics links

* Sam's Laser FAQ -- Laser Instruments and Applications

* [http://an.hitchcock.org/repairfaq/sam/laserlia.htm#liaint3]

Differences Between LEDs and Laser Diodes

* [http://donklipstein.com/laserdio.htm#diocss2]

Can I Use the Optical Pickup from a CD/DVD Player or CD/DVDROM for Interferometry?

* [http://donklipstein.com/laserlia.htm#liaint5]

Interferometers Using Inexpensive Laser Diodes

* [http://donklipstein.com/laserlia.htm#liaint4]

Laser Diodes with Built-In Beam Correction

* [http://donklipstein.com/laserdio.htm#dioldbb]

Beam Characteristics, Correction, Comparison with Other Lasers, Noise

* [http://donklipstein.com/laserdio.htm#diobcc]

Determining Characteristics and Testing of Laser Diodes

* [http://donklipstein.com/laserdio.htm#diodct]

Anatomy of Fiber-Coupled Laser Diodes

* [http://donklipstein.com/laserdio.htm#diofcld]

Laser and Parts Sources

* [http://donklipstein.com/laserlps.htm#lpstoc]

Dissection of a Blu-ray Reader Assembly

* [http://www.repairfaq.org/sam/Blu-ray/site1/index.html]

Laser beam divergence and spot size (Theory): Optics Virtual Lab: Physical Sciences: Amrita

* [http://amrita.vlab.co.in/?sub=1&brch=189&sim=342&cnt=1]

Laser Beam Profiler

* [http://en.wikipedia.org/wiki/Laser_beam_profiler]

Silicon Light Machines, Grating Light Valve(GLV)

* [http://www.siliconlight.com/en/technology/overview.html]

* drive sleds

PHR-803 sled optic questions

* [http://laserpointerforums.com/f49/phr-803-sled-optic-questions-42787.html]

Optics from a LPC-815 sled

* [http://laserpointerforums.com/f49/optics-lpc-815-sled-56026.html]

* power supply stuff

Problem with my LM317 driver

* [http://laserpointerforums.com/f38/problem-my-lm317-driver-74104.html]

Load monitoring

* [http://www.linear.com/product/LTC6101]

LDO regulator

* [http://www.micrel.com/_PDF/other/LDOBk.pdf]

* surplus parts

* [http://www.mi-lasers.com/]

* mounting parts

Diode mount (brass)

* [http://www.lillyelectronics.com/2x-brass-mount-holder-frame-m11x0-5-for-laser-diode-3-8mm.htm]

* [http://www.newport.com/Introduction-to-Positioning-Equipment/144535/1033/content.aspx]

* random parts

I wonder how you make a perfect cross-hair, maybe useful for assuring the gantry is square?

* [http://www.coherent.com/Products/?988/Cross-Hair-Line-Generators]

Or maybe you project this above the gantry, and make sure it's parallel that way

* [http://www.coherent.com/Products/?2023/StingRay-Structured-Light-Laser]

Diode Can Opener

* [http://www.thorlabs.com/thorProduct.cfm?partNumber=WR1 ]

## books

Optics by Hecht

[http://www.amazon.com/Optics-4th-Edition-Eugene-Hecht/dp/0805385665]

# 405nm

This seems like the best way to go, the 12X blu-ray writers have a diode that can be driven to 700 (mA or mW).

hmm 500mW with a real data sheet... divergence says it is a bar of diodes next to each other... not ideal

[http://www.prophotonix.com/uploads/pdfs/HL40023MG_Rev2.PDF]

### possible electronics

Ideally the system would use feedback from the laser diode can's photodiode... because after heat, brightness is the main killer of the laser... and brightness varies with temperature at a constant current... so when the laser is cool, the brightness will be different than when it's warm

* Constant current drivers

* [http://www.analog.com/static/imported-files/data_sheets/ADN8810.pdf]

* APC (automatic power control), apc laser driver

* find something to put here!

### possible lenses

if the laser is elliptical, these may help to correct it to a more spherical shape (they don't sell a mounting package for the 2 prisms though)

[http://www.edmundoptics.com/optics/prisms/specialty-prisms/anamorphic-prism-pairs/2429]

collimating lens

[http://www.edmundoptics.com/optics/optical-lenses/aspheric-lenses/blue-laser-collimating-aspheric-lenses/3362#products]

focusing lens

[http://www.edmundoptics.com/optics/optical-lenses/aspheric-lenses/precision-molded-aspheric-lenses/2123]

## CO2

[http://www.repairfaq.org/sam/laserco2.htm](http://www.repairfaq.org/sam/laserco2.htm)

# stepper links

* PDFs

* [http://users.ece.utexas.edu/~valvano/Datasheets/StepperSelection.pdf]

* [http://users.ece.utexas.edu/~valvano/Datasheets/StepperMicrostep.pdf]

|